Notes

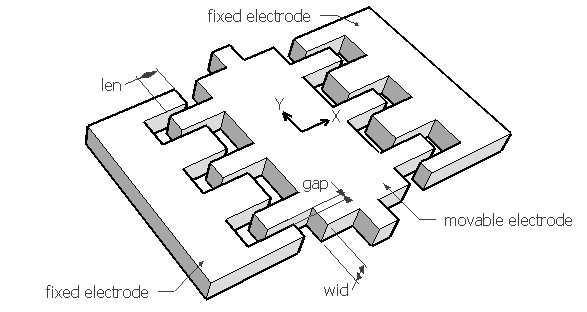

The comb drive actuator typically consists of a movable electrode consisting of one or more finger like features forming a interdigitated

comb like pattern with a fixed electrode. The interdigitated pattern ensures

that the normal force between the electrodes in Y direction are canceled out. When a voltage

is applied between the movable electrode and one fixed electrode, based on

which fixed electrode is activated, the movable electrode will move laterally

in X direction towards it. This movement will continue till the tangential

electrostatic force due to all the active fingers are balanced by the elastic

force of the spring suspension. This position is the balanced displacement and

the corresponding electrostatic force is the actuation force. Actuation force

is independent of the overlapping distance. The spring suspension is not shown

in the figure, but the comb drive is designed to move in X direction and should be prevented from moving in

Y direction. So the spring constant should be calculated

for Y axis and based on that the beam design should be done. The movable

electrode in the picture has six fingers, only three of which on one side will

be activated at one time.

Using this design form, the balanced displacement, the actuation force and the minimum spring constant to prevent Y axis movement can be estimated. Assuming the supply voltage is the critical voltage that would force the fingers to move in Y direction, the minimum spring constant required in Y axis is calculated. If the spring constant is below this value, for the given voltage, the movable electrode will become unstable and move in Y axis till it hits the fixed electrode. Keeping the spring constant in Y above this value would ensure that the comb-drive is stable.

The plot shows the relationship between the applied voltage and the lateral displacement for the given comb drive. Using the crosshair tool, the displacement for any given voltage upto 20V can be estimated.